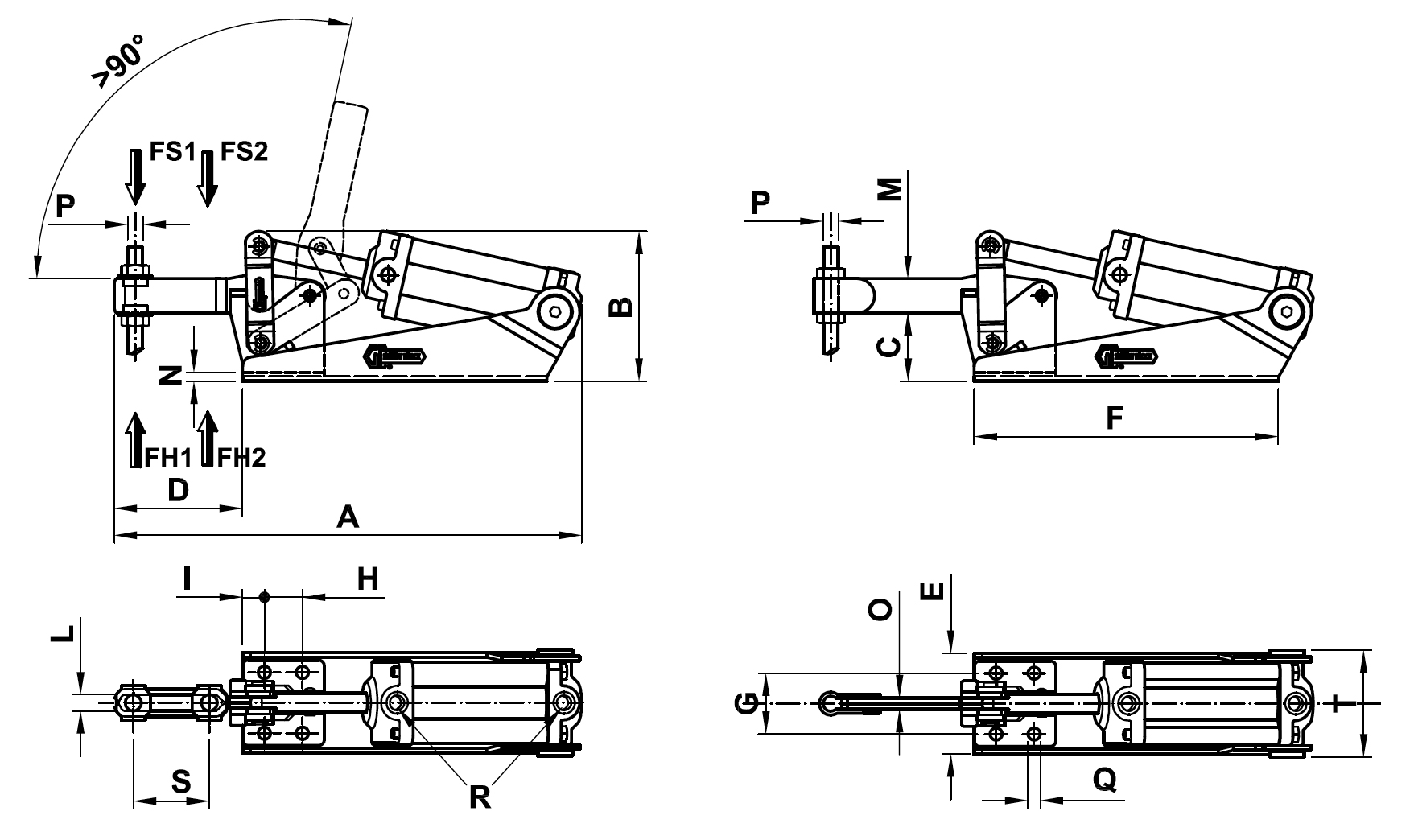

| Code | A | B | C | D | E | F | G | H | I | L | M | N | O | P | Q | R | S | T | Fh1 (daN) | Fh2 (daN) | Fs1 (daN) | Fs2 (daN) | gr |

| 2S.P70/AP3 | 163 | 51,5 | 21 | 38 | 42 | 92 | 24 | 15 | 6,5-7 | 5,2 | 11 | 4 | M5 | 4,5 | 1/8" | 20 | 45 | 70 | 145 | 50 | 75 | 500 | |

| 2S.P125/AP3 | 200 | 70,5 | 30 | 50 | 47,5 | 150 | 29 | 19 | 8-11,2 | 6,2 | 14 | 4,5 | M6 | 5,5 | 1/8" | 23 | 46 | 160 | 300 | 70 | 120 | 700 | |

| 2S.P200/AP3 | 246 | 79 | 36 | 67,5 | 53 | 160 | 32 | 20 | 11,5-12 | 8,5 | 18 | 5,5 | M8 | 6,5 | 1/8" | 40 | 56 | 220 | 350 | 90 | 150 | 1070 | |

| 2S.P300/AP3 | 304,5 | 98 | 48 | 78,5 | 74 | 195,5 | 46 | 29 | 8,5-10,5 | 10,5 | 20 | 8,5 | M10 | 8,5 | 1/4" | 42 | 66 | 270 | 450 | 120 | 240 | 2100 | |

| 2S.P400/AP3 | 360 | 107,5 | 51 | 110 | 74 | 216 | 45 | 32 | 10 | 12,5 | 22 | 10 | M12 | 8,5 | 1/4" | 66 | 80 | 300 | 640 | 140 | 260 | 3100 | |

| 2S.P70/EP3 | 163 | 51,5 | 21 | 38 | 42 | 92 | 24 | 15 | 6,5-7 | 11 | 4 | 4 | M5 | 4,5 | 1/8" | 45 | 70 | 145 | 50 | 75 | 500 | ||

| 2S.P125/EP3 | 201 | 70,5 | 30 | 51 | 47,5 | 150 | 29 | 19 | 8-11,2 | 14 | 4,5 | 5 | M6 | 5,5 | 1/8" | 46 | 160 | 300 | 70 | 120 | 700 | ||

| 2S.P200/EP3 | 248 | 79 | 36 | 69,5 | 53 | 160 | 32 | 20 | 11,5-12 | 18 | 5,5 | 6 | M8 | 6,5 | 1/8" | 56 | 220 | 350 | 90 | 150 | 1070 | ||

| 2S.P300/EP3 | 306 | 98 | 48 | 80 | 74 | 195,5 | 46 | 29 | 8,5-10,5 | 20 | 8,5 | 8 | M10 | 8,5 | 1/4" | 66 | 270 | 450 | 120 | 240 | 2100 | ||

| 2S.P400/EP3 | 362 | 107,5 | 51 | 112 | 74 | 216 | 45 | 32 | 10 | 22 | 10 | 10 | M12 | 8,5 | 1/4" | 80 | 300 | 640 | 140 | 260 | 3100 |

https://getechsrl.com//en/products/hyrax/toggle-clamps/ap3-ep3-pneumatic-toggle-clamp.html#sigProIdd4a39aa382

Hyrax - Outlet

Toggle Clamps

AP3 - EP3

Pneumatic Toggle Clamp

Features and applications

The pneumatic series can offer increased productivity with a safe and automatic operation by combining the design of the hand-operated tools and the power of air pressure. Apart from the high load capacity there are several advantages of pneumatic toggle clamps:

- Constant clamping force (FS) - independent of the operation

- Possibility of the operation of several devices at the same time

- Possibility of the activation from various points - remote control could be performed by machines.

- Different versions are available with magnetic cylinders that allow contactless positioning control to obtain electrical command pulses in particular tightening situations.

The clamp remain closed even in the case of loss of air pressure.

The manually operated equivalent of this item is in our Vertical series (see Vertical Toggle Clamp with Folded Base)

Recommendations

We recommend using a filter-reducer-lubricator group for a long and smooth operation of the cylinder, while for a long duration of the mechanical components we recommend using suitable flow regulators and calibrating the speed of the motions desired, starting from a low speed and gradually increasing this speed.

A special grease is placed between two contacting surfaces during assembly.

Material: Sheet metal and galvanized steel riveted pivots. Hardened and ground steel rotation pivots. Supporting bushes (for sizes from 200 daN and over) undergo case-hardening and grinding.

Performance:

Form AP3 with open clamping lever and two flanged washers.

Form EP3 with full clamping lever and bolt retainers.

Cylinder: Maximum operating pressure 6 bar. Maximum operating temperature 80°C.

Clamping force (Fs): 50 - 240 daN

Retaining force (Fh): 70 - 450 daN

The 2S.AAU460 model reed switch is used for detecting the position for sizes 200 and 300; model 2S.AAU450 is used for size 400. The proximity switches must be ordered separately! (See Accessories)

Spindles: To be ordered separately (see Accessories)