In this new article, we would like to introduce you to the fields of application in the case of some of our smaller product groups in our FLEXO line. This product line groups all of our products connected to vibration control and in this article we will showcase to you the smaller subcategories of the anti-vibration mountings. In general, the anti-vibration rubber buffers are designed to damp vibration and shocks created by operating machines, moving and/or unbalanced vibrating elements in order to prevent malfunctioning, noise and damage of the machine or in the health of the operator. By the end of the article, you will have a better insight into the small features that can make a big difference by choosing the right anti-vibration mounting for your applications.

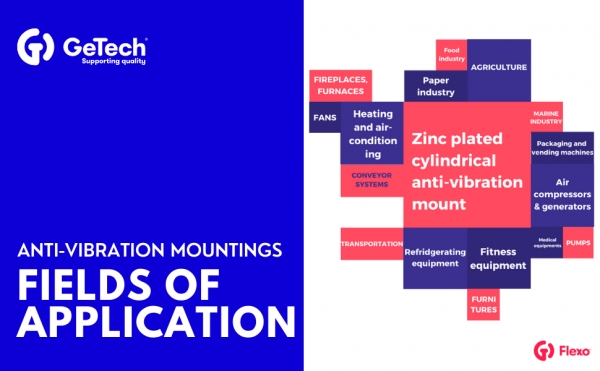

One of our most popular but probably most misunderstood products are the zinc plated cylindrical anti-vibration mountings. These - mainly small - parts are having a major role in vibration control and could be used in various fields like agriculture, heating and air-conditioning, conveyor systems, air compressors and generators, refrigerating equipment and in various fields of transportation. Due to the zinc-plated metal parts, we recommend these parts in basic applications where they are not being exposed to big extremities such as high humidity, intense exposure to fresh or saltwater and extreme heat. As these spare parts are being the core business of our company since the beginning, we developed a wide range of assortment from the most requested shapes and sizes. The most used sizes of these lines are available with two different rubber hardness (60 Shore A as standard, and 45 Shore A as soft) in order to adapt to different applications.

Another really important category in our FLEXO line is the stainless steel cylindrical anti-vibration mounts. This type of anti-vibration mounts - compared to their zinc plated colleagues - are applied in similar fields but in situations where the part must be withstanding certain conditions. These could be the weather, saltwater or humidity. Thanks to its corrosion-resistant property, stainless steel anti-vibration mountings are typically being used in the marine industry but we are also supplying many items for the food industry or as heating and air-conditioning parts. Here, in GeTech we are supplying many different anti-vibration mounts that are made following the specifications of a certain project. Our standard stainless steel anti-vibration mountings are made with AISI 304 material but upon request, we can provide them in AISI 316 as well.

A special category in our assortment is the non-cylindrical anti-vibration mountings. These mountings usually have a special shape and are used in applications when the classic antivibration mounts cannot be placed due to the lack of space or to the special design of the machinery. Despite their unique appearance they have been designed and produced in a way that they can deliver the same results just like the normal cylindrical mounts. In our standard assortment, we keep the most used shapes and sizes (like the conical and the sandglass-shaped design) but on request, we are also able to quote other special shapes, such as Type BT, CT, DP, DT, EP, KD, or Type KE (see photo gallery below) with custom size or hardness.

Along with our standard products, we are supplying more and more custom-made items for special projects. In these situations, we are always working very closely with our customers to ensure that their requirements are met 100%. In case you would need an anti-vibration mounting with certain specifications, do not hesitate to contact our team of professionals for a quotation. To discover our standard assortment of anti-vibration mountings, click here: https://www.getechsrl.com/en/products/flexo/content/cylindrical-mountings.html