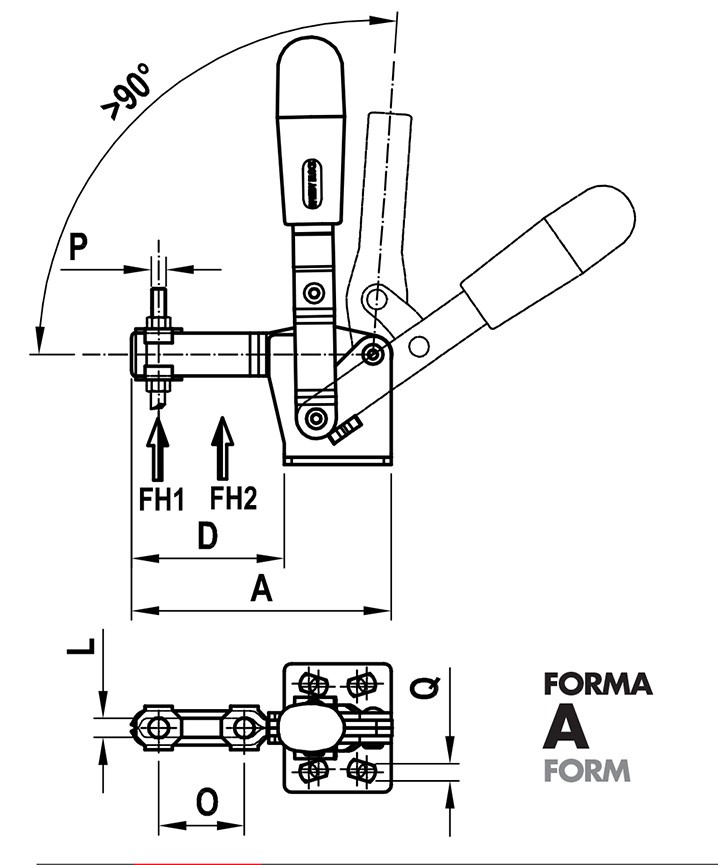

| Code | Code INOX | A | B | C | D | E | F | G | H | I | L | M | N | O | P | Q | Fh1 (daN) | Fh2 (daN) | gr |

| 2S.V75/A | 2S.V75/AX | 66,5 | 98 | 20,5 | 37,5 | 34 | 29 | 24 | 15-16 | 5,2 | 11 | 2 | 20 | M5 | 4,5 | 75 | 160 | 98 | |

| 2S.V130/A | 2S.V130/AX | 85 | 142 | 28 | 50 | 42 | 35 | 27/29 | 12,5-19 | 6,2 | 16 | 2,5 | 28 | M6 | 5,6 | 105 | 175 | 230 | |

| 2S.V230/A | 2S.V230/AX | 110,5 | 168 | 33,5 | 67,5 | 45 | 43 | 32 | 19-20 | 8,5 | 18 | 3 | 40 | M8 | 6,7 | 200 | 320 | 380 | |

| 2S.V330/A | - | 129 | 195 | 43 | 79 | 65 | 50 | 45-46 | 29-32 | 10,5 | 22 | 3,5 | 43 | M10 | 8,5 | 240 | 400 | 604 | |

| 2S.V430/A | - | 164 | 247 | 55,5 | 106 | 65 | 58 | 45 | 32 | 12,5 | 26 | 4 | 64 | M12 | 8,5 | 280 | 500 | 1100 | |

| 2S.V530/A | - | 223 | 303 | 84,5 | 143 | 95 | 80 | 70 | 50-51 | 12,5 | 32 | 7 | 90 | M12 | 12,5 | 450 | 875 | 2110 | |

| 2S.V75/E | 2S.V75/EX | 67 | 98 | 20,5 | 38 | 34 | 29 | 24 | 15-16 | 4 | 11 | 2 | M5 | 4,5 | 75 | 160 | 100 | ||

| 2S.V130/E | 2S.V130/EX | 86 | 142 | 28 | 51 | 42 | 35 | 27-29 | 12,5-19 | 5 | 16 | 2,5 | M6 | 5,6 | 105 | 175 | 235 | ||

| 2S.V230/E | 2S.V230/EX | 112 | 168 | 33,5 | 69 | 45 | 43 | 32 | 19-20 | 6 | 18 | 3 | M8 | 6,7 | 200 | 320 | 390 | ||

| 2S.V330/E | - | 130,5 | 195 | 43 | 80,5 | 65 | 50 | 45-46 | 29-32 | 7 | 22 | 3,5 | M10 | 8,5 | 240 | 400 | 604 | ||

| 2S.V430/E | - | 166 | 247 | 55,5 | 108 | 65 | 58 | 45 | 32 | 10 | 26 | 4 | M12 | 8,5 | 280 | 500 | 1100 | ||

| 2S.V530/E | - | 225 | 303 | 84,5 | 145 | 95 | 80 | 70 | 50-51 | 10 | 32 | 7 | M12 | 12,5 | 450 | 875 | 2110 |

https://getechsrl.com/en/products/hyrax/toggle-clamps/a-e-vertical-toggle-clamps-with-folded-base.html#sigProIdd7030bcf33

Hyrax - Outlet

Toggle Clamps

A - E

Vertical Toggle Clamps with Folded Base

AISI 304 stainless steel items indicated with an 'X' in their coding (e.g. 2S.V75/AX)

Features and applications

In case of vertical toggle clamps even a lower power input results in a high clamping force. Thanks to this, vertical toggle clamps have one of the most versatile applications in the industrial field. During the closing of the clamp, the clamping lever is guided laterally to ensure greater stability against possible transverse stresses during working on the component. The clamp has a big and clear opening, like this the insert, change and remove of the working piece is unproblematic.

A special grease is placed between two contacting surfaces during assembly.

Fields of application: woodworking, welding, plastic injection molding, CNC machining, various types of assembly, automotive industry, engineering.

Material: Galvanized steel or AISI 304 stainless steel

Riveted pivots: Galvanized steel or AISI 304 stainless steel

Handles: Red polyurethane - resistant to oils, grease and other chemical agents.

Performance:

Form A and form AX with open clamping lever and two flanged washers.

Form E and form EX with full clamping lever and bolt retainers to be welded in the desired position and angle.